Exploring the Features of Nomad CNC

- Adam Sultana

- Oct 20

- 4 min read

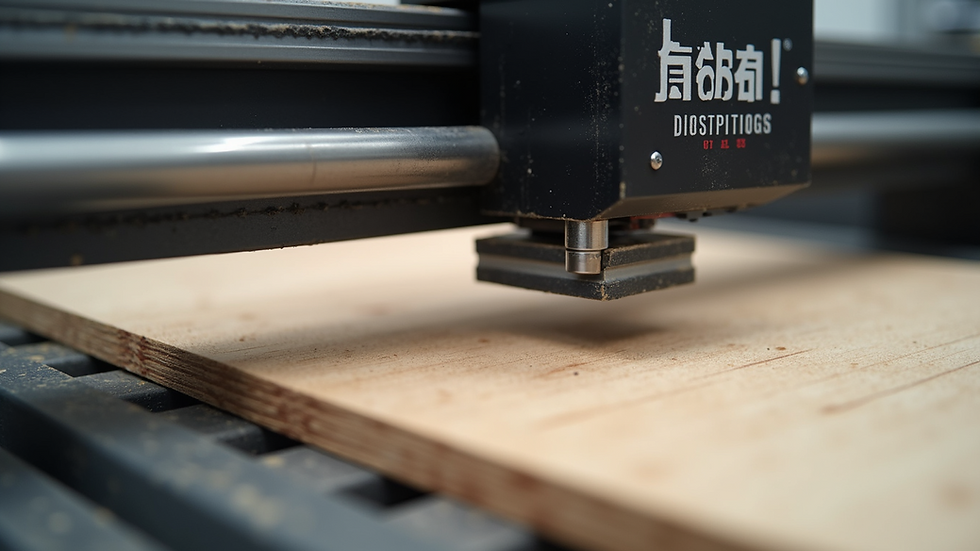

When it comes to custom manufacturing, especially for van fit-outs and bespoke products, having the right tools makes all the difference. We’ve found that CNC machines open up a world of possibilities for creating durable, high-quality builds that stand out. Today, let’s dive into the features of Nomad CNC and see why it’s becoming a favourite for turning adventurous ideas into reality.

Key Features of Nomad CNC

Nomad CNC offers a blend of precision, versatility, and user-friendliness that makes it ideal for custom projects. Here are some standout features that caught our attention:

Compact and Portable Design: Unlike large industrial machines, Nomad CNC is designed to fit comfortably in smaller workshops or even mobile setups. This portability is perfect for those who need flexibility without sacrificing power.

High Precision Cutting: With its robust spindle and advanced motion control, it delivers clean, accurate cuts on a variety of materials including wood, plastics, and soft metals. This precision is essential for detailed van fit-outs or custom product parts.

User-Friendly Interface: The machine comes with intuitive software that simplifies the design-to-production process. This means less time troubleshooting and more time creating.

Durability and Build Quality: Built with high-quality components, Nomad CNC is designed to last. Its sturdy frame reduces vibrations, ensuring consistent results even on longer jobs.

Versatile Material Compatibility: Whether you’re working with plywood for cabinetry or aluminium for structural parts, this machine handles it all with ease.

These features combine to make Nomad CNC a reliable partner for anyone looking to craft unique, custom pieces with confidence.

How Nomad CNC Supports Custom Van Fit-Outs

Custom van fit-outs require precision and adaptability. Every millimetre counts when you’re optimising space and functionality. Nomad CNC shines in this area by allowing us to:

Create Custom Panels and Fixtures: We can design and cut panels that fit perfectly into the van’s interior, ensuring a seamless finish.

Produce Durable Components: The machine’s ability to work with tough materials means we can build long-lasting fixtures that withstand the rigours of travel.

Speed Up Production: With automated cutting, we reduce manual labour and speed up turnaround times, which is crucial when working on multiple projects.

Experiment with Complex Designs: The precision and software compatibility allow us to try intricate patterns or functional shapes that would be difficult to achieve by hand.

For adventurers who want a van that’s truly tailored to their lifestyle, these capabilities make a huge difference.

What is the easiest CNC software to use?

Choosing the right software can be just as important as the machine itself. For those new to CNC or looking for a smooth workflow, ease of use is key. Nomad CNC pairs well with software that balances power and simplicity. Some of the easiest CNC software options include:

Carbide Create: This is a popular choice for beginners and professionals alike. It offers a straightforward interface for designing 2D parts and generating toolpaths. It’s perfect for creating custom van components without a steep learning curve.

Fusion 360: While more advanced, Fusion 360 offers comprehensive CAD/CAM capabilities with plenty of tutorials and community support. It’s great for those ready to take their designs to the next level.

Easel: A web-based option that’s very beginner-friendly. It’s ideal for quick projects and simple designs, making it a good match for small custom jobs.

The key is to pick software that fits your comfort level and project needs. Nomad CNC’s compatibility with these programs means you can start creating right away, no matter your experience.

Practical Tips for Getting the Most Out of Your CNC Projects

To make the most of Nomad CNC’s features, here are some practical tips we’ve learned along the way:

Plan Your Design Thoroughly: Spend time on your CAD files to avoid errors during cutting. Double-check measurements and toolpaths.

Choose the Right Material: Match your material choice to the project’s demands. For van fit-outs, lightweight plywood or aluminium sheets often work best.

Test Cuts First: Always run a test cut on scrap material to ensure settings are correct. This saves time and material in the long run.

Maintain Your Machine: Regular cleaning and lubrication keep the machine running smoothly and extend its lifespan.

Use Clamps and Fixtures: Secure your workpiece firmly to prevent movement during cutting, which can affect precision.

Leverage Community Resources: Join forums or local groups to share tips and troubleshoot issues. The CNC community is incredibly supportive.

By following these steps, you’ll enjoy a smoother, more productive CNC experience.

Why Choose Nomad CNC for Your Next Project?

If you’re looking for a CNC solution that combines quality, ease of use, and versatility, Nomad CNC is a strong contender. It’s especially suited for those who want to create custom van fit-outs or bespoke products that stand the test of time. Here’s why it stands out:

Local Expertise: Based in Western Sydney, Nomad CNC understands the unique needs of local adventurers and van owners. They’re committed to helping you bring your ideas to life with precision and care.

Tailored Solutions: Whether you need a one-off custom piece or a series of parts, they can adapt to your project size and complexity.

Support and Guidance: From design advice to post-production support, their team is ready to assist you every step of the way.

Quality Assurance: Every product is crafted with attention to detail, ensuring durability and functionality.

For anyone ready to take their custom manufacturing to the next level, exploring what Nomad CNC offers is a smart move.

If you want to learn more or get started on your own custom project, check out Nomad CNC and see how they can help turn your adventurous ideas into reality.

Comments