5/11/2024: How to Cut Acrylic on Your CNC - Tips, Tricks, and New Product Highlights for Sydney Nomads!

- Adam Sultana

- Nov 5, 2024

- 4 min read

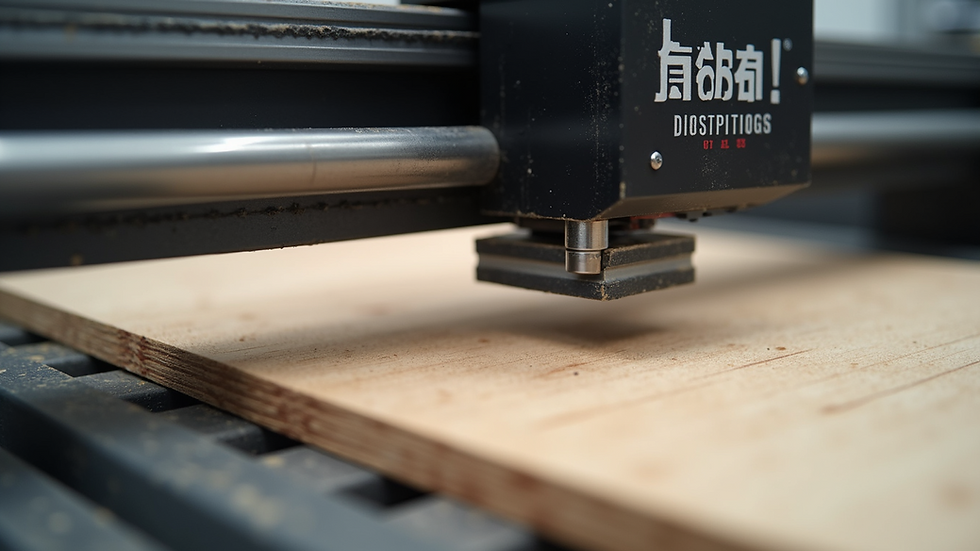

If you've ever found cutting acrylic with your CNC machine challenging, you're not alone. Many makers and DIY enthusiasts in Sydney and beyond aim to create stunning projects with this versatile material. Today, we’ll explore essential tips for cutting acrylic safely and effectively with your CNC machine. We will also highlight some exciting new products from Nomad CNC and share strategies to successfully market your creations in your local area.

Understanding Acrylic and Its Properties

Before starting your project, it's crucial to understand acrylic. This material, known for its glass-like appearance, comes in two main types: cast and extruded. Cast acrylic is typically easier to cut and has a clearer finish, making it the preferred choice for projects such as trophies and signs. For instance, cast acrylic boasts a transparency of about 92%, compared to 87% for extruded acrylic.

While working with acrylic can be rewarding, it’s important to be aware that it is more brittle than materials like wood or metal. Without proper handling, it can crack or chip during the cutting process. Always ensure your workspace is set up to minimize the risk of damaging the sheets while positioning and securing them.

Selecting the Right Tool Bits

Choosing the right tool bit is essential for quality results when cutting acrylic. Opt for a single-flute or up-cut spiral bit. These bits effectively remove chips and prevent melting during cutting.

Recommended Tool Bits:

1/8" Single-Flute Up-Cut Spiral Bit: Ideal for detailed work, such as intricate designs and small projects.

1/4" Up-Cut Spiral Bit: Suitable for larger cuts, this bit allows faster feed rates, enhancing productivity for bigger sheets.

Make sure to keep your bits sharp! Dull bits can lead to jagged edges and inconsistent cuts, which can ruin your final product. Regular maintenance of your bits can increase their lifespan by up to 50%, ensuring smoother operation.

Feeds and Speeds: Get It Right

Understanding feeds and speeds is crucial for successful acrylic cutting. Each machine has different capabilities, so perform some trials to determine what works best.

Key Definitions:

Feed Rate: The speed at which the material moves into the cutting bit. For cutting acrylic, a good starting range is 60-120 inches per minute (IPM), depending on material thickness.

Spindle Speed: This refers to the number of rotations per minute (RPM) of the cutting tool. For optimal cutting of acrylic, aim for a range of 10,000 to 20,000 RPM.

Best Practices:

Start Slow: If you are new to cutting acrylic, begin with lower speeds and feeds. This helps you gain confidence and understand how the material behaves.

Incremental Adjustments: After testing lower settings, gradually increase the feed rate and spindle speed to find a balance that prevents chipping or melting.

Take Breaks: When cutting large pieces, allow your CNC machine to cool down, particularly in hot environments. Overheating can lead not only to melting but also wear on your machine.

Cutting Techniques to Avoid Melting

Acrylic has a tendency to melt if the cutting bit generates excessive heat. Here are some techniques to help ensure clean cuts:

Air Assist: Use an air assist feature on your CNC machine. It helps cool the acrylic and clears away chips, greatly reducing the chances of melting. Studies show that using air assist can increase cut quality by up to 30%.

Depth of Cut: Making shallower cuts can be more manageable when working with acrylic. Consider making multiple passes instead of cutting through the entire material at once. This reduces pressure on the acrylic, preserving its clarity and finish.

New Products from Nomad CNC

As a vibrant creative hub in Sydney, we are thrilled to introduce some new products crafted with our CNC machine.

Product Highlights:

Custom Acrylic Signs: We now create unique, personalized signs for events or businesses. For example, we designed a beautiful wedding welcome sign that showcased the couple's names and wedding date with LED backlighting for extra flair.

Acrylic Displays: Perfect for showcasing art or jewelry, our customizable displays cater to various themes and occasions. Recently, we made an acrylic display stand featuring adjustable heights for a local artisan’s jewelry line, resulting in a significant sales increase of 25%.

These innovative products utilize high-quality materials paired with skilled craftsmanship, illustrating how acrylic can transform into functional and beautiful works of art.

Marketing Your Creations

Finding customers can often be the toughest part of running your creative business. If you’re based in Sydney, targeting local neighborhoods can be a smart strategy to promote your acrylic creations.

Target Local Customers:

Community Events: Participate in local art fairs, maker spaces, or craft markets to connect with fellow creators and potential customers who value your work.

Networking: Forge connections with local artists and businesses that might be interested in collaborations or purchasing your products.

Online Communities: Join local forums or Facebook groups focused on crafts and makers. Sharing your journey and expertise might attract individuals seeking unique, custom solutions.

The Joy of Connecting with Passionate Customers

One of the most rewarding aspects of working with acrylic and CNC is connecting with enthusiastic customers. It brings immense satisfaction when someone truly appreciates the art behind your work.

Engaging with fellow creators can lead to fruitful collaborations that spark even greater creativity. Finding customers who share your passion for craftsmanship adds a unique joy to your artistic journey.

Final Thoughts

Cutting acrylic on your CNC machine in Sydney offers a world of creativity and possibilities. Remember to select the right bit, understand feeds and speeds, and employ proper cutting techniques to design stunning pieces. Additionally, don’t overlook the importance of marketing your work within your community; you never know who might appreciate the artistry you pour into your projects.

As you embark on your next CNC journey, embrace the learning experience, celebrate your progress, and connect with other enthusiasts. Happy crafting, Sydney Nomads!

Comments