Mastering the Art of 3 Axis CNC Cutting: Achieving Precision, Interlocking Parts, and Balancing Bit Quality with Feed and Speed

- Adam Sultana

- Nov 14, 2024

- 3 min read

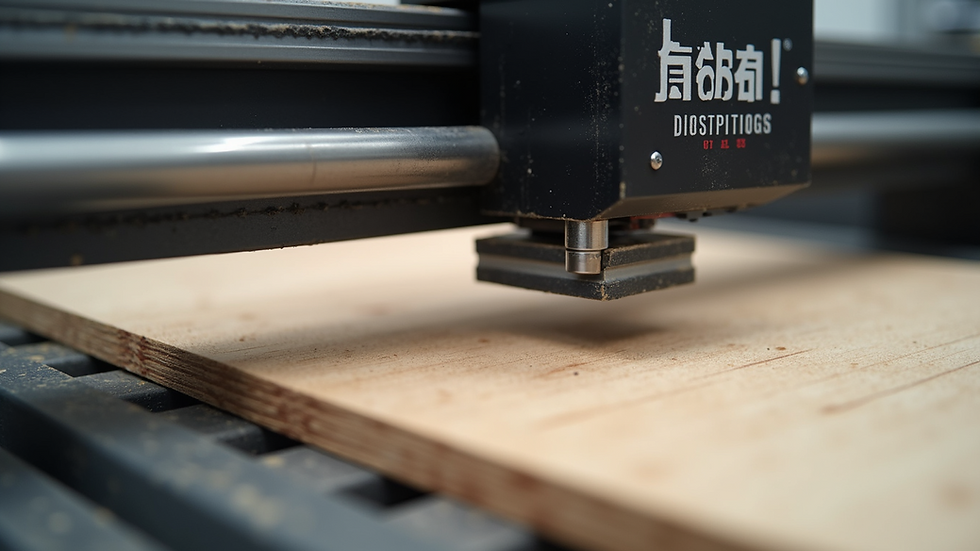

3 Axis CNC cutting has transformed design and manufacturing, enabling makers and engineers to create intricate and precise cuts. As you explore CNC technology, understanding the complexities of challenging cuts, interlocking parts, and the importance of accuracy is vital. Balancing bit quality, feed rates, and speed accuracy adds to the challenge of achieving precision. In this post, we will delve into these crucial elements, offering practical insights for mastering the art of 3 Axis CNC cutting.

The Importance of Precision in CNC Machining

Precision is fundamental in CNC machining. Even a tiny error in tolerance can turn a functional part into waste. For instance, if you're creating components for a high-performance engine, even a 0.1mm discrepancy might lead to failure.

The first step to achieving precision is understanding your design. Modern CAD software, such as SolidWorks or Fusion 360, allows thorough visualization of cuts. This capability helps anticipate potential challenges, especially for difficult cuts that require complex tool paths.

When designing for 3 Axis CNC machining, consider the machine's capabilities. Knowing your machine's travel limits and spindle speeds allows for practical and achievable designs. For instance, if your CNC machine has a maximum spindle speed of 18,000 RPM, designing cuts that require higher speeds is unrealistic.

Navigating Difficult Cuts and Interlocking Parts

Difficult cuts can present significant challenges in CNC machining. These cuts often require special tool paths or multiple setups. For example, creating a complex gear with both internal and external cuts may need different tool configurations to complete the design effectively.

Interlocking parts add complexity as well. Each component must fit together accurately to ensure proper functionality. For example, when constructing a wooden puzzle with interlocking pieces, even a slight imperfection in one cut can lead to pieces that do not fit. Therefore, it is essential to factor in tolerances and the material characteristics influencing fit.

Mixing difficult cuts with interlocking components demands meticulous attention to detail. Ensuring designs account for material expansion and contraction is crucial since wood can expand up to 12% depending on humidity. This factor might affect fitting if not considered during the design phase.

The Balance Between Bit Quality and Feed Rates

Bit quality significantly impacts the outcome of CNC projects. High-quality bits create precise cuts that low-quality bits may struggle with. For instance, using a carbide bit can yield cleaner edges, with studies showing they can last up to five times longer than standard HSS (high-speed steel) bits.

Feed rate, the speed at which the bit penetrates the material, plays a crucial role in cut quality. If you set a feed rate too fast, you risk damaging both the bit and workpiece. Conversely, a slow feed rate may generate excessive heat, leading to material burning.

Finding the right balance often requires some experimentation. For example, when working with hardwood, a typical feed rate might be around 50 inches per minute. However, for metals, this number can drop to 10-15 inches per minute due to their density.

Investing in high-quality carbide bits, while sometimes pricier, is generally justified by their longevity and superior finish. The difference in cost may be offset by the savings on frequent bit replacements and better quality finishes.

Accuracy vs. General Errors in CNC Cutting

Despite our best efforts, errors can occur during CNC machining. Factors like tool wear, machine calibration, and environmental conditions can lead to inaccuracies. For instance, a minor calibration error of 0.05mm can cause a ripple effect, resulting in significant discrepancies in cut dimensions.

To minimize risks, regular maintenance of your CNC machine is essential. Keeping your machine calibrated ensures cuts remain within desired tolerances. Additionally, inspecting tooling for wear can prevent inaccuracies. A worn bit, for example, may result in a cut that is off by up to 0.2mm.

Using probing systems and measurement tools during the machining process offers real-time feedback on tolerances. This approach helps identify potential errors before they escalate, saving both time and resources.

Mastering CNC Machining Techniques

Excelling in 3 Axis CNC cutting requires a comprehensive understanding of design principles, materials, and the balance between various factors like bit quality, feed rates, and machine accuracy. While achieving this balance can be daunting, the rewards are substantial.

Dedicating time to perfect each aspect—from selecting high-quality bits to designing interlocking parts—enables creators to produce items with impressive precision and functionality. As CNC technology evolves, new capabilities will emerge, empowering innovators who commit to honing their skills.

Mastering CNC machining is about more than just cutting. It's about designing with a deliberate focus on precision and quality. Embrace the challenges you encounter, learn from each project, and watch your skills grow as you navigate the exciting world of 3 Axis CNC cutting.

Comments