Setting Up for Success – Behind the Scenes at Nomad CNC

- Adam Sultana

- Nov 4, 2024

- 2 min read

Published on 4th November 2024

At Nomad CNC, we believe that a seamless setup is the foundation of a successful project. Our business setup practices are designed to ensure every job, from a single custom part to bulk production, is delivered efficiently, accurately, and sustainably. Today, we’re excited to share a behind-the-scenes look at how we approach new projects – using our latest job setup as an example, creating large acrylic signage for a commercial client.

Step 1: Understanding Our Client’s Needs

We begin each project with an in-depth consultation, which is essential for defining both the scope and the finer details. For this large acrylic signage project, the client wanted a bold, durable solution that could endure the rigours of a busy environment while standing out visually. Working through their specific needs allowed us to establish clear design goals and production timelines.

Step 2: Business Setup Practices and Workflow Organisation

Once we understand the project requirements, we move into setup mode. We follow a few core practices to ensure smooth workflows:

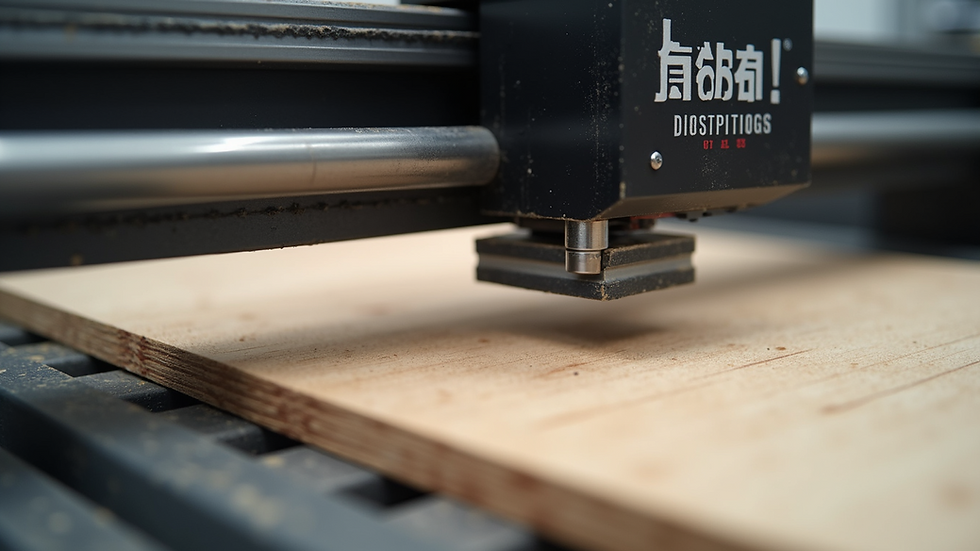

Planning and Scheduling: Every job is carefully planned and scheduled. For this signage order, we allocated time specifically for design refinement, material selection, and cutting. Our CNC router, a 3-axis machine (2400x1200), is perfect for handling large acrylic sheets, and we lined up the production run to avoid any overlap with other orders, ensuring this job receives undivided attention.

Material Sourcing and Preparation: Sustainable material sourcing is key to our setup practices. We selected premium, eco-friendly acrylic for this project, ensuring the finished product is not only visually striking but also aligns with our sustainable business practices.

Design Confirmation and Prototyping: Before cutting, we confirm design details with the client. For this signage, we created a prototype of the design, allowing the client to see the dimensions and lettering style before we started the full production.

Step 3: Setting Up the Job – From Initial Cut to Final Finish

With the setup complete, we moved into production. Working with acrylic requires careful temperature and speed control to avoid any burn marks or imperfections. Our setup practices ensure that each step is methodically managed, from loading the sheet to positioning the cutter and testing speeds.

After the pieces were cut, our team focused on the finishing touches – smoothing the edges and preparing mounting holes to make the installation process seamless. Each stage of the process is checked against our quality standards, giving our clients confidence that every product we produce meets our exacting specifications.

Why Proper Job Setup Matters

A well-executed setup isn’t just about efficiency; it’s about delivering on promises. Our business setup practices allow us to keep lead times accurate and manage multiple projects simultaneously without sacrificing quality. For clients, this means faster turnarounds, clearer communication, and peace of mind knowing their project is in capable hands.

Nomad CNC – Quality CNC Work and Exceptional Service

For commercial and industrial clients in Sydney, Nomad CNC offers much more than standard CNC cutting. Our approach combines sustainable practices, a streamlined setup process, and personalised service that focuses on understanding and exceeding client expectations.

Ready to discuss your next project? Contact Nomad CNC today to see how our expert setup practices can bring your ideas to life with efficiency and precision.

Comments